Validation of performance of polymeric geogrid in reinforced wall application

ABSTRACT

Tensar uniaxial geogrids are molecularly oriented polymeric grid structures developed for tension resistant inclusions in soil walls and slopes. When stressed the geogrid must be capable of sustaining the load without rupture over the design life of the structure. The earliest use of high-density polyethylene grids in civil engineering applications was in the 1960’s in order to reinforce volcanic ash fill in a railway embankment in Japan. This paper describes the design considerations for geogrid used in a reinforced soil wall at the New Plymouth Mail Centre that was constructed in January 1995. These walls incorporating a treated timber facing were built with local Taranaki Ash. Part of the wall up to 3.5 m high was deconstructed in February 2019 as the site was being developed into a two-storey commercial building and no longer required the truck access that the reinforced soil wall formed part of. Sections of geogrid were removed from the wall and sent to the manufacturer for testing. The results of the testing are presented and compared to the original design considerations.

INTRODUCTION

The ability to maintain specified material characteristics over a selected period is defined as durability. The service life of a structure incorporating geosynthetic reinforcement depends for a large part on the durability of the geosynthetic. In all cases the primary resin used in the manufacture of the geosynthetic is mixed or formulated with antioxidants, screening agents, fillers or other materials to satisfy the service life for the intended application. In the context of geosynthetics used for soil reinforcement a service life of up to 120 years is required. The likely environmental and in-service conditions need to be considered when determining the durability of the individual geosynthetic reinforcement product.

This paper focuses on the durability requirements and testing of one specific geosynthetic reinforcement and compares the predicted performance against the results from testing of exhumed product after 24 years of service.

DURABILITY OF POLYMER REINFORCEMENT

The long-term mechanical behaviour of the geosynthetic is highly dependent on the polymer used, additive formulation and the environmental conditions that the geosynthetic will be exposed to over the full-service life of the structure.

Polyethylene

The polymer polyethylene (PE) is a polyolefin belonging to the hydrocarbon group. The different types of PE used in the manufacture of geosynthetics are mainly linear co-polymers formed by catalytic polymerisation under low temperature and pressure (Rodriguez, 1996). PE is categorised into the following classes found in the manufacture of geosynthetics:

High density polyethylene (HDPE), density >0.940 g/ml

Medium density polyethylene (MDPE), density = 0.926 – 0.940 g/ml

Linear low-density polyethylene (LLDPE), density = 0.919 – 0.925 g/ml

The physical and mechanical properties of PE are highly sensitive to density and the selection of PE class is governed by the function of the geosynthetic product.

Durability of PE is dependent on the kind of polymer, morphology, residual heavy metals from catalysts and chemical impurities from the polymer processing.

Geogrids for use in soil reinforcement are manufactured from HDPE are typically formulated as shown in Table 1.

Table : Composition of HDPE Geogrid by weight percentage.

| Polymer Resin | Resin | Carbon Black | Additive |

| High density polyethylene (HDPE) | 96 – 98 | 2 – 3 | 0.25 – 1 |

Chemical Degradation

Polymers degrade principally due to chemical reactions with the environment. Polyolefins are generally known to be highly resistant to a wide range of chemicals with polyethylene being the most commonly used polymer in the manufacture of geomembranes for the waste containment industry. They are also inert to aqueous solutions of acids and alkalis likely to be found in engineering soils.

Polyolefins including polyethylene principally degrade by oxidation which is a reaction between polymer and molecular oxygen. Increasing temperature can increase the rate of degradation.

The chemical and physical structure of the polyolefin can have a strong influence on the oxidation. The permeability decreases as density (i.e. crystallinity) of the polymer increases. HDPE therefore has greater resistance to oxidation than LLDPE. If the polymer is stretched during the manufacturing process, then the polymer becomes more orientated resulting in a much denser amorphous phase and higher crystallinity which retards diffusion of oxygen into the polymer.

Long-term antioxidants are an additive to the manufacturing process of polyethylene products to retard oxidation over the service life of the product at the service temperature.

Manufacturers of HDPE (pipe, geomembrane etc) have their own masterbatch formulations for production that include antioxidants to meet the specific environmental exposure requirements for the intended application and carbon black to resist the effects of ultra-violet light. There is however no guidance on what minimum values are allowable for the polymer used in the manufacture of HDPE uniaxial geogrids.

PD ISO/TR 20432:2007, Guidelines for the determinations of the long-term strength of geosynthetics for soil reinforcement, is the current practice in Europe which states:

- The durability of the reinforcing element shall be based on life-time assessment according to the guidance in PD ISO/TR 20432:2007. Durability screening tests are not acceptable for predicting durability and associated reduction factors for the full design lifetime.

Tensar Geogrids

Tensar geogrids are manufactured by extruding a sheet of high-density polyethylene (HDPE) resin, punching holes, then stretching in one direction only. Due to this method of manufacture the resulting geogrids are termed “uniaxial”, with high strength and stiffness in the direction of stretching, and they are used principally for reinforced soil applications, such as retaining walls, steepened slopes and bridge abutments.

Tensar geogrids were first developed in the 1980’s with Tensar SR2 being the first commercially used grade, followed by the introduction of Tensar SR55, SR80 and SR110 in 1986.

Durability tests for environmental stress cracking were carried out which demonstrated that the additives and process used to manufacture the SR geogrids resulted in no significant difference between the long term creep performance in air and when immersed in a surfactant solution which was known to encourage the development of environmental stress cracking.

The manufacturing and product testing for Tensar SR geogrids was independently assessed by the British Board of Agrément (BBA) and certified in 1988 for use within reinforced soil retaining walls to achieve a design life of 120 years. Detail Sheet 2 of this certificate states that, with respect to durability, Tensar SR55 geogrids may be used in most fills normally encountered in civil engineering practice without regard to corrosion. The grids will not deteriorate from normal exposure to sunlight on construction sites, nor when buried in wet soil, and have good resistance to biodegradation. The certificate further states that data was examined with regards to resistance to ultra-violet light, and that the durability assessment was based on data relating to resistance to biological attack, chemical resistance and stress cracking resistance as mentioned previously.

It should be noted that considerable progress has been made since the publication of the Tensar SR55 BBA Certificate with regards to advice and procedures for the assessment of durability of geosynthetics. In European practice, the main guidance document for geosynthetic reinforcement is EN 13251:2016, entitled “Geotextiles and geotextile-related products – Characteristics required for use in earthworks, foundations and retaining structures”. Annex B (normative) of this standard covers durability aspects, including assessment based both on EN 12224:2000 for weathering of all products and ISO 13438:2004 for oxidation of polyolefins, and gives the following warning: “the tests described in this annex do not allow for the determination of reduction factors.. (and) are screening tests to show the ability of a product to serve for a certain time”. EN 12224:2000 states “this is an index test to differentiate between products with little or no resistance to weathering and those which do have this resistance”, whereas both ISO 13438:2004 and EN 14030:2001 state “the data obtainable are suitable for screening purposes but not for deriving performance data such as lifetime, unless supported by further evidence”.

Therefore, in order to compliment the durability screening tests carried out on Tensar geogrids, it is important that life-time prediction studies are carried out, following guidance as given in PD ISO/TR 20432:2007 as mentioned in the previous section. Lifetime prediction studies can take a variety of forms including long term accelerated exposure tests in various environments, normally carried out at high temperature, and sometimes at high pressure. However, another important source of information on life-time performance comes from testing exhumed samples of geogrid which have been in service for extended periods of time. The case study described in this paper is a very good example of such an investigation.

NEW PLYMOUTH MAIL CENTRE

Soils Report

The site is located on a volcanic ash. The excavated volcanic ash obtained from the site was found to be suitable as backfill for the reinforced soil retaining wall and for the ramp construction.

The soils report lists the following recommended strength parameters for the compacted volcanic ash:

Table 2: Soil properties.

| Property | Value |

| Bulk density | 15 kN/m3 |

| Cohesion | 20kPa |

| Friction angle | 25o |

There were no Atterberg limits presented in the soils report however a value of >40 for plasticity index (PI) has been reported for volcanic ash found in the Taranaki region (Wesley, 1992).

Soils derived from andesitic ash from Mt Taranaki typically have a pH of between 5.5 to 6.0.

Wall Design

The requirement for this site was to build a wall over an existing stormwater culvert having a retained height of up to 3.5m and a face angle of 84o from the horizontal. The wall formed an access ramp to the site to support the mail centre B-train truck traffic which was modelled as a 16kN/m2 temporary live load.

The design incorporated Tensar SR55 geogrids located at 400mm vertical spacing for the first metre increasing to 600mm vertical spacing for the remained of the wall (Figure 1). Each geogrid was wrapped around a 100 SED Grade 1 pole and connected back onto itself using an approved bodkin. This ensured that the full strength of the geogrid could be realised at the timber pole face.

600

600

600

600

400

3500

2700

40mm asphalt

150mm M/4 base

100mm SE40 sub-base

Tensar SR55

200mm granular drainage

200

2×1×0.5 gabion

2×1×1 gabion

2×1×0.5 gabion

2m dia Class Y stormwater culvert

Timber pole facing from Taranaki ash

Security fence

Figure 1: Typical section over culvert

The properties of Tensar SR55 used in the design of the reinforced soil are detailed in Table 3.

Table 3: Properties of Tensar SR55

| Property | Value |

| Polymer | HDPE |

| Minimum carbon black content | 2% |

| Quality control strength Tult | 55.0kN/m |

| Characteristic strength * | 20.5kN/m |

* in-soil temperature 20oC

Construction of the reinforced soil timber walls took place in January 1995.

Product exhumation and testing

Product exhumation

In February 2019 part of the timber wall was deconstructed as the site was being developed into a two-storey commercial building and no longer required truck access that the reinforced soil wall formed part of. Samples of geogrid were removed from the 2.0m high wall section and sent to the manufacturer, Tensar International in the United Kingdom for testing.

Testing

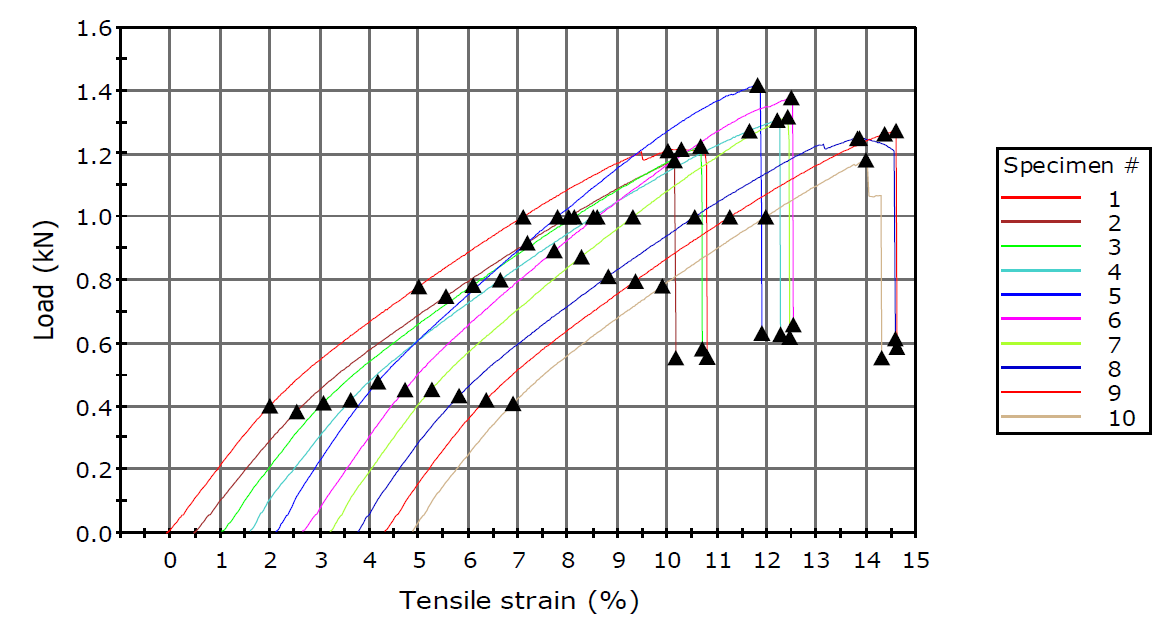

The recovered samples were of insufficient size to carry out a full set of wide-width tensile tests, so that single-rib tensile tests on five specimens (Figure 4) were carried out at a strain rate of 20%/minute (64mm/minute) which is the rate of extension required in the current standard ISO 10319:2015. Further testing was carried out on ten single-rib specimens at an extension rate of 100mm/minute (31%/minute) which was the test procedure used for quality control testing of Tensar SR55 at the time of development and manufacture, before the current test methods had been developed.

The results of testing the recovered samples of Tensar SR55 following the both the current standard and the original procedure are presented in Figures 2 and 3 and are summarised in Table 4.

Table 4: Results of tensile testing at a strain rate of 20%/minute and 100mm/minute

| Tensar SR55 | Specification | Exhumed Sample

20% per minute |

Exhumed Sample 100mm per minute |

| Strength @ Maximum Load (kN/m)* | 57.0 | 57.32 | 57.33 |

| Strength @ 2% strain (kN/m) | 16.5 | 19.84 | 19.28 |

| Strength @ 5% strain (kN/m) | 31.7 | 37.5 | 36.9 |

* The samples and tests were conditioned and carried out at 20oC which is the normal standard used for quality control testing.

Figure 2: Single rib load strain test results for strain rate of 64mm/minute

The tests at 100mm/minute were well in excess of the specification requirements (see Table 4) although there was more variation (Figure 3).

Figure 3: Single rib load strain test results for strain rate of 100mm/minute

Some of the grid was quite bent and distorted so that some variation could be a consequence of the exhumation, packing and sending to United Kingdom through the post.

|

|

Figure 4: Images of single rib test and sample

CONCLUSION

The design of reinforced soil retaining walls using polymeric reinforcement must consider the long-term durability properties predicted from real time investigations and accelerated tests. The challenge facing the Industry is that if a geosynthetic reinforcement material is HDPE then there is a common notion that published durability data for high quality products may be assumed to apply to all HDPE products, provided that they have similar appearance and quality control data. However, this is far from the actual case as durability of HDPE polymer is influenced by resin quality, additives incorporated into the masterbatch and the manufacturing process. The geomembrane industry has undergone a lot of changes introducing rigorous manufacturing and installation quality control standards as the result of a number of costly failures. Adequate durability testing of polymeric geogrids is essential to cover the expected environmental conditions to give designers confidence that the polymeric reinforcement will meet the service life requirements. The advice provided in PD ISO/TR 20432:2007 represents the current state-of-the-art in European practice, and as outline in Section 2, frequently quoted durability screening test results are not appropriate for determining life-time predictions nor reduction factors to take into account environmental effects in design. This can only be done by life-time prediction tests, either using accelerated long-term laboratory tests or by recovering samples which have been in service for extended periods of time. The results from the case study presented here add to the knowledge and growing body of data concerning durability of HDPE geogrids.

The results on the exhumed samples of Tensar SR55 geogrid show no loss in tensile strength over the 24 years of service life and support the durability testing that the manufacturer has carried out on their range of uniaxial geogrids to justify the partial factors applied for durability in reinforced soil wall designs.

REFERENCES

Archer, G.C., 1994, Geotechnical Investigation Proposed Mail Centre Dawson/King Streets, New Plymouth

British Board of Agrément, 1988, Roads and Bridges Agrément Certificate No 88/43 First Issue

CUR 243 Durability of Geosynthetics, Stichting CURNET, Gouda, The Netherlands, 2012

EN 12224. Geotextiles and geotextile-related products – Determination of the resistance to weathering. BS EN 12224:2000, British Standards Institution, London, United Kingdom.

EN 13251. Geotextiles and geotextile-related products – Characteristics required for use in earthworks, foundations and retaining structures. BS EN 13251:2016, British Standards Institution, London, United Kingdom.

EN 14030. Geotextiles and geotextile-related products – Screening test method for determining the resistance to acid and alkaline liquids. BS EN 14030:2001, British Standards Institution, London, United Kingdom.

Hsuan, Y.G., Schroeder, H.F., Rowe, K., Müller, W., Greenwood, J., Cazzuffi, D., Koerner, R.M., 2008, Long-Term Performance and Lifetime Prediction of Geosynthetics,. EuroGeo4, Edinburgh, UK.

ISO 10319. Geosynthetics – Wide-width tensile test. BS EN ISO 10319:2015, British Standards Institution, London, United Kingdom.

ISO 13438. Geotextiles and geotextile-related products – Screening test method for determining the resistance to oxidation. BS EN ISO 13438:2004, British Standards Institution, London, United Kingdom.

ISO/TR 20432. Guidelines for the determination of the long-term strength of geosynthetics for soil reinforcement. PD ISO/TR 20432:2007, British Standards Institution, London, United Kingdom.

Rodriguez, F. 1996 Principles of Polymer Systems, 4th Edition. Taylor and Francis, pp. 732.

Wesley L.D., 1992, Some Residual Strength Measurements on New Zealand Soils, Sixth Australian-New Zealand Conference on Geomechanics.